ArcelorMittal Group

ArcelorMittal Hunedoara is managed by a team of professionals with extensive experience in the steel industry. Currently, the position of General Manager is held by Silviu Manolache Mirzac, appointed to this position in July 2024. Previously, the management was provided by Pawar Shimoga Dayananda Rao and Lutz Bandusch Johannes. The Board of Directors also includes members with international expertise, such as Juan Domingues and Amit Kumar.

Enthusiasts – Devotees – Professionals

We live in an era of remarkable progress, where innovation and human ingenuity are driving unprecedented global development.

Technology plays a key role in this transformation, as do the materials that build our world. As one of the world leaders in steel production and mining, ArcelorMittal Hunedoara has a clear responsibility in this process.

Steel remains as relevant to the future success of our society. As one of the few materials that is completely reusable and recyclable, steel will play a crucial role in building the circular economy of the future. It will continue to evolve, becoming smarter and more sustainable.

At ArcelorMittal Hunedoara, we aim to contribute to building a better world through smart steels. Steels produced through innovative, more efficient processes that consume less energy and emit significantly less carbon. Steels that are cleaner, stronger and reusable. Steels for electric vehicles and renewable energy infrastructure that will support the transformation of societies in this century.

We foster this culture of innovation by putting research and development at the heart of our operations. We have some of the best and brightest in the field – engineers who work with us to tackle the most complex challenges.

At ArcelorMittal Hunedoara, we are dedicated to developing innovative products and solutions in the steel industry. We are determined to adapt to the latest technologies and practices, to be leaders in innovation and sustainability. From developing technologies that reduce the carbon footprint of steel, to new construction solutions that transform the built environment, to improving production processes and automation, we are ready to adapt and adopt the latest technologies and practices in the steel industry.

We ensure that our products meet the highest standards of quality and safety, so that we can offer our customers the best solutions in the steel industry. We are proud to be part of a community of passionate and dedicated professionals, working together to achieve our goals and to be leaders in innovation and sustainability in the steel industry.

History

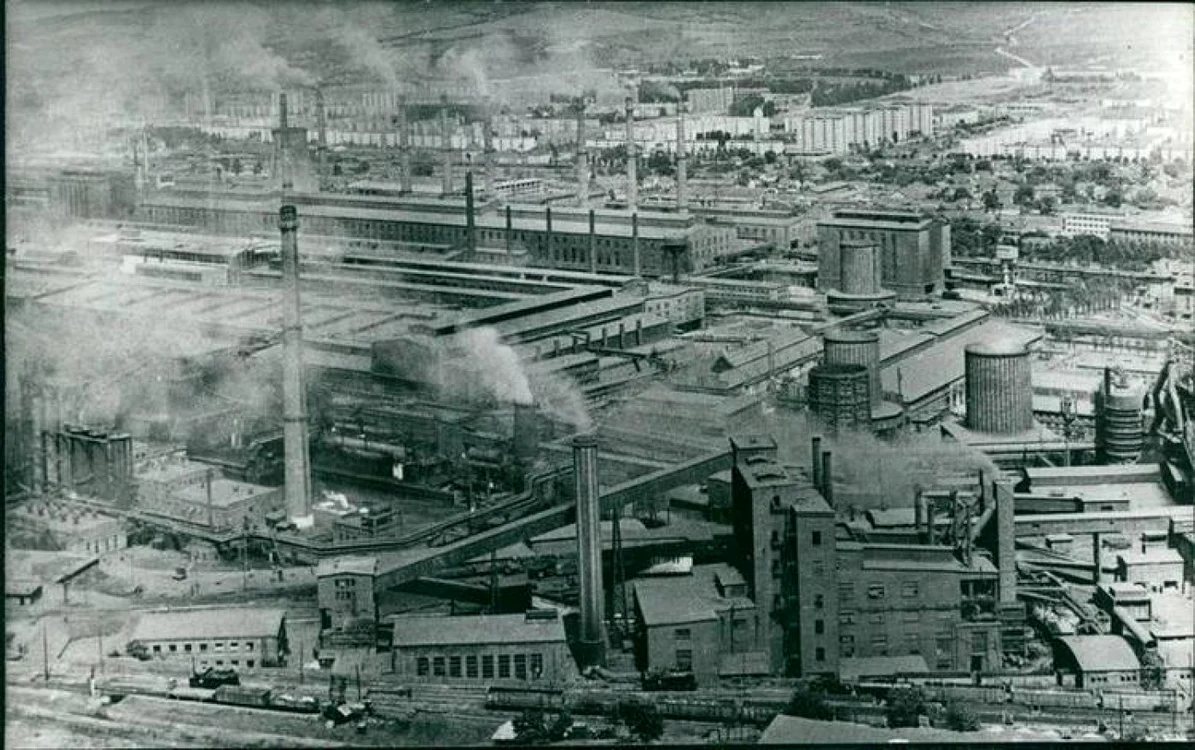

ArcelorMittal HUNEDOARA S.A. Hunedoara, located in Hunedoara, Hunedoara-Santuhalm Road, no. 4, is a company with a manufacturing flow consisting of an electric steel mill, continuous casting and rolling mill, the result of over a century of development of the HUNEDOARA IRON PLANTS.

The construction of the steel plant on the territory of the city of Hunedoara was approved in November 1881. In August 1882, the construction of two 110 m3 blast furnaces began. The first batch of pig iron was discharged on June 12, 1884. Blast furnace no. 2 was put into operation in May 1885.

In July 1885, furnace no. 3 of 140 m3 was put into operation, in 1890 furnace no. 4 of 288 m3 and in 1902 furnace no. 5, based on the designs of furnace no. 4.

During the commissioning of furnace no. 3, experiments began on the production of cast iron steel, using a pre-annealing furnace and a Bessemer converter. After the commissioning of furnace no. 3, construction of a steelworks began, with two Siemens-Martin furnaces of 12 tons capacity and two Bessemer converters, commissioned in 1892. The entire production of ingot steel was delivered for processing to other plants. In 1899, the Bessemer workshop was taken out of service for economic reasons.

Due to the economic situation, steel production ceased in 1904. In 1919, the Hunedoara Iron Works became the property of the Romanian state.

Between 1927 and 1941, the plant went through two stages of development:

- between 1927 and 1937 the processing sector develops, especially of cast iron;

- Between 1938 and 1941, a Siemens-Martin steel mill was built with four 25 t/batch furnaces and an 800 mm rolling mill, thus achieving a complete metallurgical cycle.

A particularly intense period of development began in 1958, with the commissioning of the Siemens Martin steelworks no. 2, the 1000 mm bloomery and the heavy section rolling mill. The development of production capacities continued with the construction and commissioning of 20 t, 50 t and 100 t electric furnaces, the 1300 mm bloomery, the semi-finished products rolling mills and the finishing rolling mills (wire, small profiles and medium profiles). In parallel with the development of production capacities, the laboratories for analysis and testing were built and modernized, which ensured the necessary precision for determining the quality characteristics of the products. The professional competence of the staff and the technical equipment ensured the production of products with sales possibilities on the world market.

In 1991 the company was organized into a commercial company, registered with the Trade Register under number J 20/41/91.03.04. ArcelorMittal HUNEDOARA SA (SC Siderurgica SA Hunedoara) ranks first in the national production of long products.

Investments in the field of steel processing are in an advanced stage of implementation. Since December 1998, steel casting has been carried out on the continuous casting plant for semi-finished products for seamless pipes and blooms for re-rolling. These capacities will ensure the improvement of the quality of the respective product ranges and the reduction of manufacturing costs. In June 1999, the Siemens Martin steelworks was removed from the steel production flow.

The launch of the nuclear energy program required the development of the first quality assurance programs. In 1981, a Quality Assurance Collective was formed, which drew up and monitored the application of a quality assurance program for products intended for heavy water plants. In 1983, the quality assurance program was adapted to the nuclear regulations and the norms established by the regulatory body, the manufacturing authorization was obtained for products intended for the Cernavoda nuclear power plant, and a series of steel grades and rolled sizes were approved for the manufacture of nuclear power plant equipment.

During the same period, ArcelorMittal HUNEDOARA SA (SC Siderurgica SA Hunedoara) produces a series of products specific to the aeronautical industry, obtaining their homologation, type certification and system authorization.

The policy and objectives of the management in the field of quality required the documentation and implementation of a quality system, in accordance with the requirements of the international standards of the ISO 9000 series. The SR EN ISO 9002 standard from 1995 – Quality systems: MODEL FOR QUALITY ASSURANCE IN PRODUCTION, ASSEMBLY AND SERVICE was adopted as the model of the quality system.

In 1997, TÜV CERT Süddeutschland certified the quality system's compliance with the reference standard DIN EN ISO 9002/1994, and in 2000, the quality system certification was extended.

After a restructuring completed in 2003, the company was privatized by the acquisition of the majority stake by the Anglo-Indian concern LNM Holdings, the company's name becoming ISPAT Siderurgica SA Hunedoara, later changed to SC Mittal Steel HUNEDOARA SA, with the merger of Ispat Internaţional with LNM Holding into Mittal Steel. Since 2007, the company has been part of the largest metallurgical concern in the world - ArcelorMittal and is called ArcelorMittal Hunedoara SA.

The restructuring program of the ArcelorMittal group also involved a series of activities related to the closure of some production sectors and the greening of other sectors already closed/under conservation, some of which were carried out through the compliance program established with the authorities.

In 2010, the work of modernizing the heavy section rolling mill was started, and it will also produce some new profiles, including economic profiles. The investment value, consisting of the modernization of the propulsion furnace, the modernization of the thickening stand, the complete change of the rolling line and the modernization of the adjustment, is 43.4 million euros. It started with the modernization of the furnace whose performance parameters are 80 t/hour - heated bloom and a consumption of 45 m3/h of methane gas consumed. The entire adjustment infrastructure was changed and equipment relocated from other units of the ArcelorMittal Group was installed. The infrastructure was also changed and a completely new rolling line was installed, with 12 stands in line, with 2 rolling trains. The most important equipment in the new facility is the flow straightening machine, 2 packaging machines and a binding machine.

Another important investment started in 2011 and expected to be completed in 2012 is the one in specific equipment for work safety, namely the lifeline equipment in all departments of the company where there is specific work at height as well as equipment with blocking equipment for all devices that transport or use energy – the LOTO system. This investment was made due to the implementation of fatality prevention standards at the Corporation level and the achievement of the planned performance level in this regard.

In 2015, the VD vacuum treatment plant was completed, which contributes to the improvement of

steel quality through degassing, thermal and chemical homogenization, acceleration of refining reactions (desulfurization, deoxidation) of the metal melt, obtaining high-purity steels with superior physicochemical properties.

Management team

ArcelorMittal Hunedoara este condusă de o echipă de profesioniști cu experiență vastă în industria siderurgică. Directorul General în funcție este Mihaela Craciun care a fost numita in functie pe 1 Decembrie 2025 ,Înaintea sa, conducerea a fost asigurată de către Silviu Manolache Mirzac, Pawar Shimoga Dayananda Rao, Doru Petrescu, Amit Kumar, Remus Pățan, printre alții. De asemenea, Consiliul de Administrație este format din membri cu expertiză internațională, precum Augustine Kochuparampil, Risto Naumov si Jeyachandran Rajasekaran. Toată echipa de conducere este dedicată să asigure o gestionare eficientă și responsabilă a companiei, urmărind să ofere produse de calitate superioară și să contribuie la dezvoltarea durabilă a comunității.